Sealing Stormwater Tanks For A Dublin Data Center

Resources → Case Studies

Sealing Stormwater Tanks For A Dublin Data Center

Resources → Case Studies

Market

Stormwater

Challenge

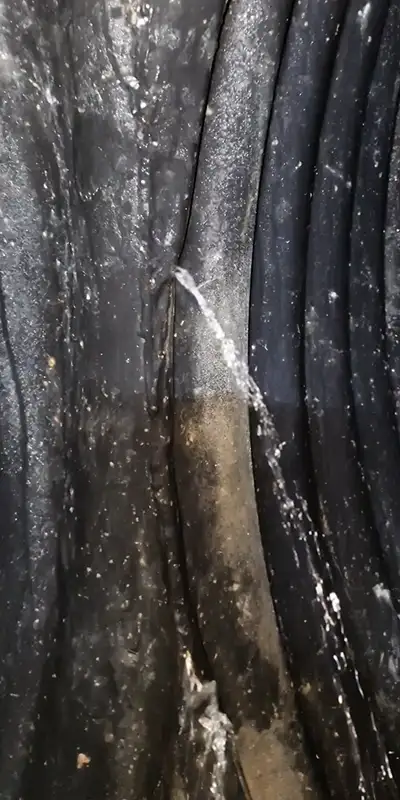

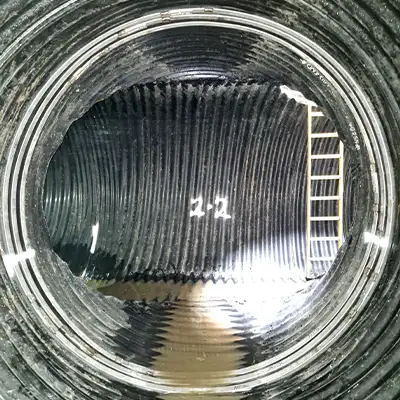

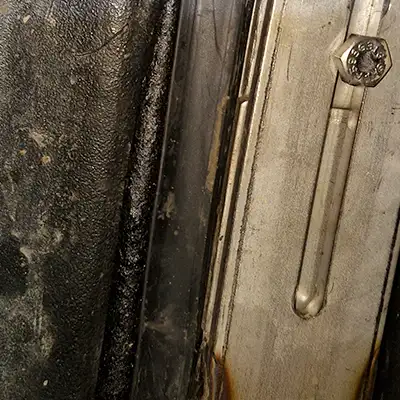

A Dublin Data Center faced significant issues with six stormwater retention tanks, which were experiencing multiple leaking points, some of which were gushing. Previous repair attempts had failed, with repairs buckling and no longer firmly pressing against the interior tank walls. Inspection revealed some joints were separated, and previous repairs had begun to corrode. The leaks threatened the integrity of the stormwater management system, risking operational disruptions and potential environmental concerns. The client did not wish to dig and replace, but the need for a reliable, long-term solution was critical to restore system functionality and prevent further deterioration.

Engineered Solution

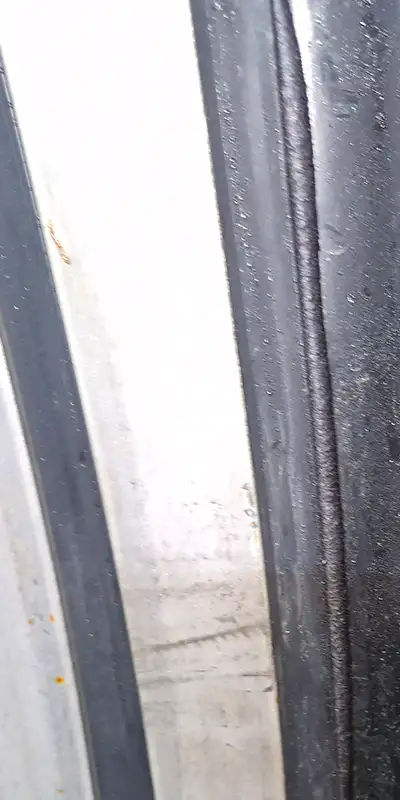

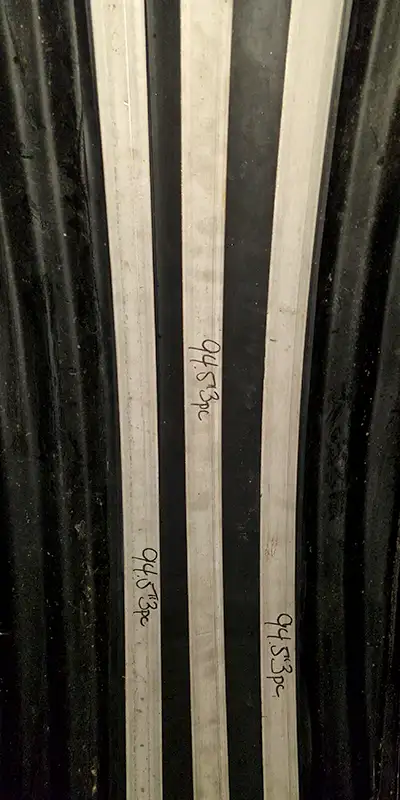

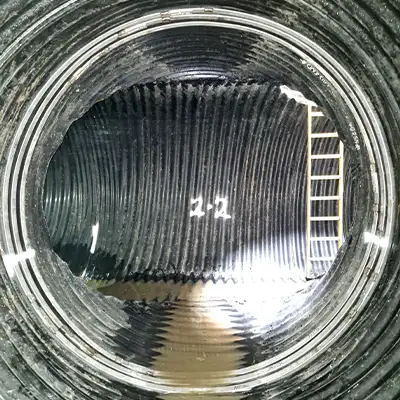

The project utilized HydraTech’s HydraTite Internal Pipe Joint Seals to address the leaking joints in the stormwater retention tanks. Specifically, 42 standard-wide and 3 extra-wide HydraTite seals were custom-fabricated for the 94.5” corrugated steel circular pipes, as this size was not part of HydraTech’s standard inventory. Each seal was secured with three retaining bands to ensure a tight, durable fit. For areas with less extensive damage, gel injections were employed as a repair method to address minor compromised points, providing a comprehensive approach to the restoration.

Scope

The project encompassed the repair of six stormwater retention tanks within 94.5” corrugated steel pipes. The scope included the custom fabrication of 45 HydraTite seals (42 standard-wide and 3 extra-wide), each installed with three retaining bands, and the application of gel injections for less severe damage points. Before seal installation, the corrugated pipe surfaces were filled at the repair areas to create a smooth sealing surface, as required for proper HydraTite performance. Once the voids were filled, the rubber sleeve was placed over each repair point, the retaining bands were expanded to the specified pressure, and locked in place with a wedge, finishing the installation. Ciaran Gaughan was the foreman who oversaw the four-man crew for this installation. The entire project took 25 days, 20 of which were spent installing HydraTite seals.

Solution

The installation of the custom HydraTite Internal Pipe Joint Seals and gel injection successfully functioned as a trenchless solutioneliminating the need for disruptive excavation or pipe replacement— saving the client time, cost, and future risk. The system is now fully operational, ensuring reliable stormwater management for this Dublin Data Center. The durable, long-term repair solution prevented further water loss and environmental risks, while the custom fabrication and efficient installation process saved the customer significant time and cost compared to alternative replacement options. The project was completed on schedule, meeting all performance expectations and providing a robust, lasting solution.

Special Thanks To James Lloyd, Underground Systems & Sewer Repair

This case study was made possible by the copious amount of images and videos supplied by James.

Just like to thank Caleb and HydraTech, for their amazing product and can’t wait to use them again in the near future. Amazingly fun to install, considering the condition we had to install the seal in…fast and to the point. Literally

Ciaran Gaughan

Project Foreman, USA Ltd. / USSR Ltd.